Plastics Poyamide 66 Raw Material is known for its overall durability and performance in various environmental conditions, including cold environments. Several factors contribute to the long-term durability of Nylon 66 resin in cold temperatures:

Chemical Stability:

Nylon 66 is chemically stable and resistant to many chemicals, including those present in cold environments. This stability contributes to the material's resistance to degradation over time.

Low-Temperature Impact Resistance:

Nylon 66 typically maintains good impact resistance at low temperatures. This property is essential for applications in cold environments where materials may experience sudden impacts or loads.

Toughness and Flexibility:

Nylon 66 exhibits toughness and flexibility, even in cold conditions. These characteristics contribute to the material's ability to withstand mechanical stresses without becoming brittle.

UV Resistance:

Nylon 66 has good resistance to ultraviolet (UV) radiation, which can be present in outdoor environments. UV resistance helps prevent degradation and color changes, contributing to long-term durability.

Moisture Resistance:

While Nylon 66 can absorb moisture, the material's moisture resistance is generally good. Properly compounded and processed Nylon 66 can maintain its mechanical properties in cold and damp conditions.

Resistance to Environmental Factors:

Nylon 66 is resistant to environmental factors such as humidity, saltwater, and atmospheric conditions commonly found in cold climates. This resistance contributes to its long-term durability.

Fatigue Resistance:

Nylon 66 exhibits good fatigue resistance, which is crucial for applications subjected to repeated cycles of stress and strain. This property enhances the material's ability to endure long-term use in cold environments.

Dimensional Stability:

The material's low coefficient of thermal expansion and good dimensional stability contribute to its long-term durability. These properties help Nylon 66 maintain its shape and structural integrity over extended periods in cold conditions.

Resistance to Cracking:

Nylon 66 is less prone to cracking compared to some other plastics, especially at low temperatures. This resistance to cracking enhances the material's durability in cold environments.

Additives and Reinforcements:

Depending on the application, Nylon 66 formulations may include additives and reinforcements to enhance specific properties. For example, the addition of glass fibers can improve stiffness and strength, contributing to long-term durability.

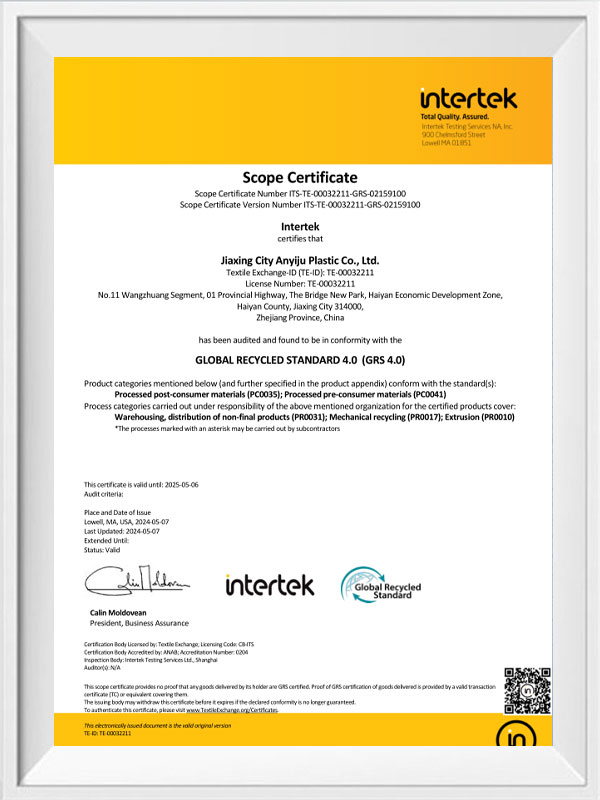

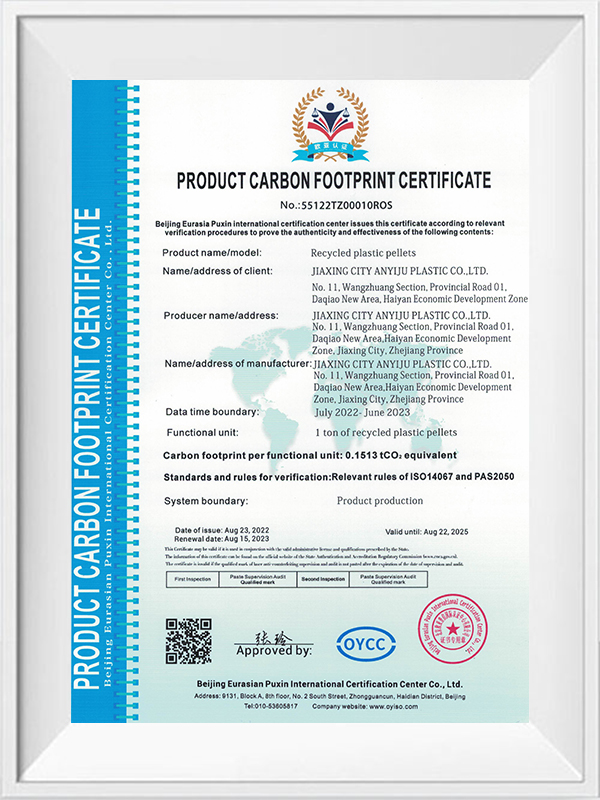

Compliance with Standards:

Nylon 66 is commonly used in applications where compliance with industry standards and specifications is essential. Meeting these standards ensures that the material is suitable for long-term use in specific environments.

While Nylon 66 demonstrates good durability in cold environments, it's important to consider the specific requirements of the intended application. Proper design, material selection, and adherence to recommended processing guidelines contribute to maximizing the long-term performance of Nylon 66 resin in cold conditions. Manufacturers often conduct testing and evaluations to validate the material's suitability for extended use in challenging environments.

简体中文

简体中文 English

English