Post-Industrial Recycled (PIR) plastics, including recycled Polyamide (PA) such as Nylon, find applications across various industries. The use of recycled PA in PIR plastics contributes to sustainability efforts by repurposing industrial waste.

PIR plastics recycled PA can be used in automotive applications for manufacturing various components, including interior parts, under-the-hood components, and exterior trims.

Recycled PA fibers can be used in the textile industry to produce fabrics for apparel, including clothing, activewear, and outerwear.

Various consumer goods can benefit from recycled PA, such as the production of containers, packaging materials, and household items like kitchenware.

PIR plastics recycled PA may be utilized in the production of industrial equipment and machinery components due to its strength, durability, and resistance to wear.

The strength and durability of recycled PA make it suitable for the manufacturing of sporting goods, including equipment like ski bindings, racket frames, and bicycle components.

Recycled PA can be used to manufacture housings and components for electronic devices, contributing to both durability and environmental sustainability.

PIR plastics recycled PA can find applications in construction materials, including pipes, fittings, and components used in various building and infrastructure projects.

Recycled PA can be used in the production of packaging materials such as films, sheets, and containers, providing a sustainable alternative to traditional packaging.

Recycled PA can be incorporated into the manufacturing of furniture components, providing durability and sustainability in furniture production.

Some medical devices and equipment may use recycled PA for components that require strength, durability, and resistance to sterilization processes.

These applications demonstrate the versatility of PIR plastics recycled PA in various industries, providing a sustainable solution for the production of diverse products. Manufacturers and consumers increasingly value recycled materials for their environmental benefits and contributions to circular economy initiatives.

PIR plastics are sourced from post-industrial waste, which includes manufacturing scrap, offcuts, and other plastic materials generated during industrial processes.

Recycling Process:

The recycling process for PIR plastics involves collecting industrial plastic waste, sorting it based on polymer types, cleaning and processing the material, and then re-extruding or molding it into new products.

Material Characteristics:

Nylon 6, or Polycaprolactam, is a type of polyamide known for its excellent mechanical properties, toughness, and resistance to abrasion. When recycled, the aim is to maintain these properties as much as possible.

Applications:

Recycled PA Polycaprolactam can find applications in various industries, including automotive, textiles, consumer goods, and more. Its versatility makes it suitable for a range of products.

Quality Control:

Quality control measures are implemented throughout the recycling process to ensure that the recycled Nylon 6 resin meets certain standards and specifications. This may involve testing for mechanical properties, purity, and other relevant characteristics.

Environmental Impact:

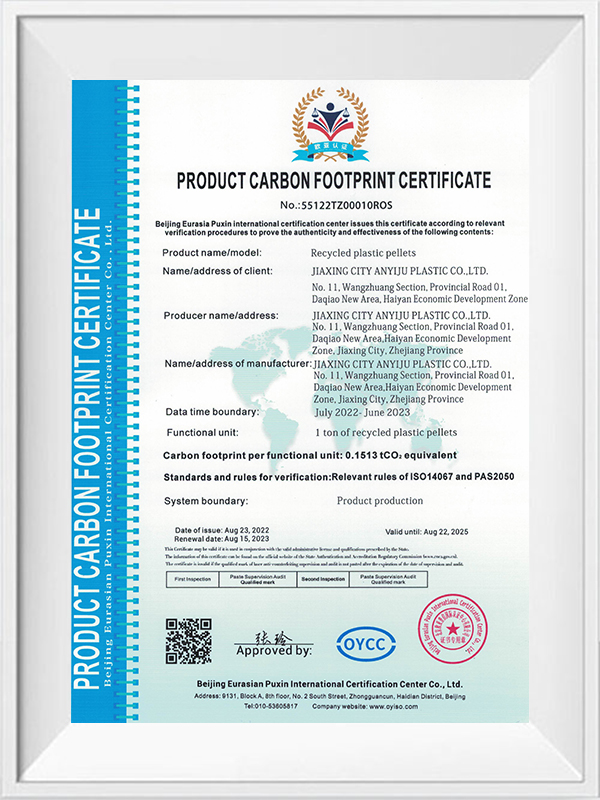

The use of post-industrial recycled materials, like PIR plastics, contributes to reducing the environmental impact of plastic waste by reusing materials that would otherwise be discarded.

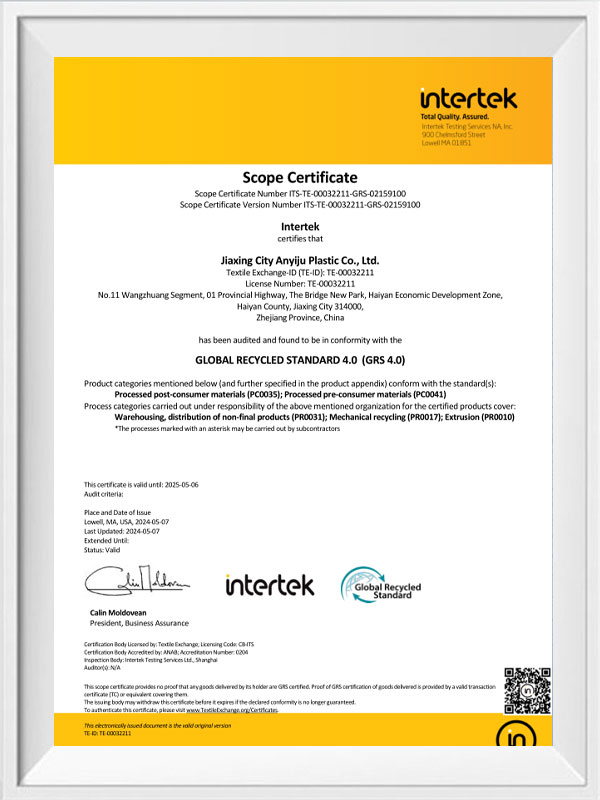

Certifications and Compliance:

Manufacturers working with recycled PA Polycaprolactam may adhere to specific certifications or standards to validate the quality and sustainability of their products.

Traceability:

Traceability is crucial in the recycling industry. Having a system to trace the source of recycled materials ensures transparency and helps maintain the integrity of the recycled product.

Economic Considerations:

The use of recycled materials can have economic benefits, such as potentially lower production costs compared to using virgin materials, depending on market conditions and availability.

Application-Specific Characteristics:

Manufacturers may tailor the properties of recycled PA Polycaprolactam to suit specific applications. This could involve adjusting formulations or using additives to enhance certain features.

简体中文

简体中文 English

English