The cost of

Polypropylene Plastic Pellet can vary primarily based on several elements, which includes market situations, the precise grade of PP, and the provider. Generally, PP is thought for being a fee-effective thermoplastic fabric, however its rate can be prompted by using various factors. Here are some concerns while evaluating the price of PP to different substances or formulations:

Base Cost:

As a baseline, PP is regularly considered to be greater cost-powerful in comparison to a few other engineering thermoplastics. It is less steeply-priced than substances like polycarbonate (PC) or polyether ether ketone (PEEK), for instance.

Supply and Demand:

Like any commodity, the cost of PP is influenced by using deliver and call for dynamics. Fluctuations in oil expenses, as PP is derived from petroleum, can impact its fee. Additionally, marketplace demand for PP can influence pricing.

Additives and Formulations:

The price of PP can vary depending on the particular formulation and any additives or reinforcements blanketed. For example, high-performance or distinctiveness formulations can be extra highly-priced than general grades.

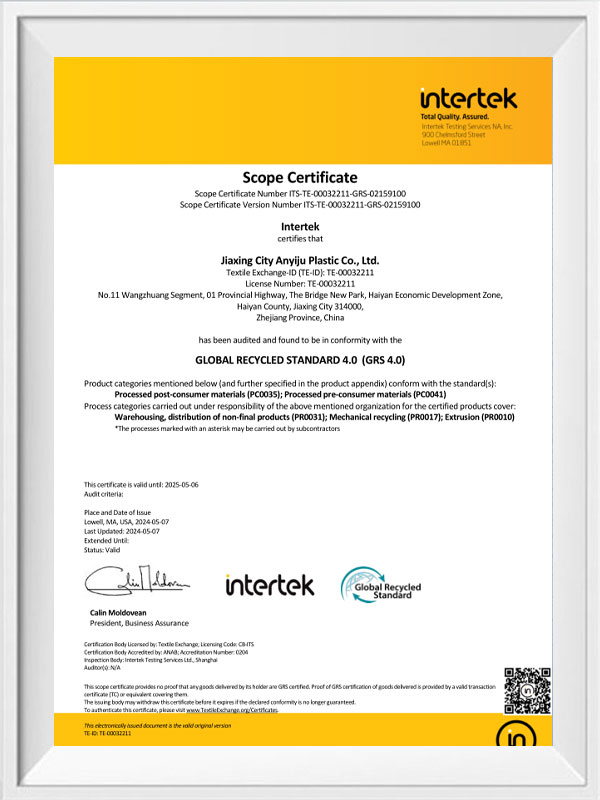

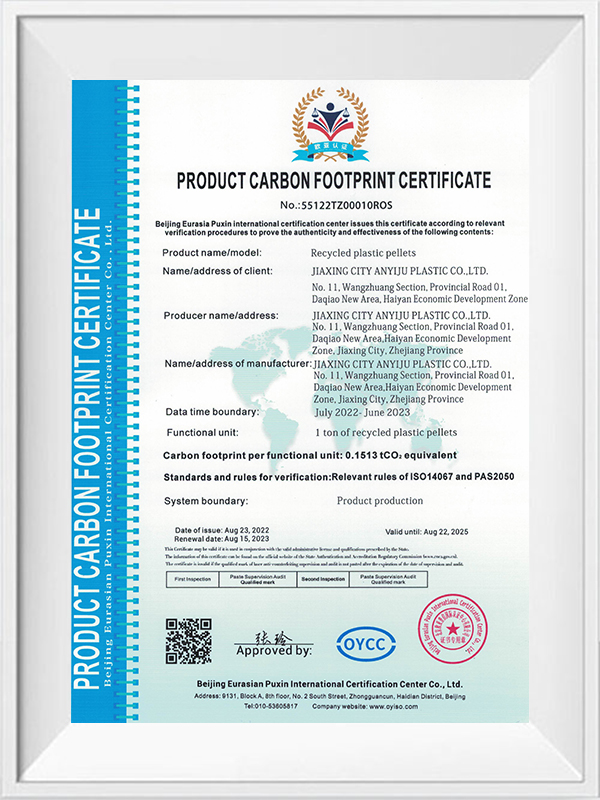

Recycled vs. Virgin PP:

Recycled polypropylene (PCR) may be extra fee-competitive compared to virgin PP as it makes use of publish-patron or post-business recycled substances. The cost gain will depend on factors together with the provision and value of recycled feedstock.

Comparisons with Other Materials:

When comparing the price of PP to different substances, it's crucial to consider the unique necessities of the software. While PP can be greater fee-powerful in some instances, the suitability of the material for the meant reason should be a primary attention.

Processing Efficiency:

PP is thought for its ease of processing, and its fee-effectiveness extends to manufacturing approaches. The material's precise waft traits and low processing temperatures contribute to cost-green injection molding, extrusion, and other processing methods.

Availability and Geographic Factors:

The value of PP also can be prompted via factors which include regional availability, transportation costs, and nearby market situations. Prices may additionally vary in extraordinary regions of the world.

Bulk Purchases and Agreements:

Purchasing in bulk or setting up long-time period supply agreements with suppliers may also provide possibilities for price financial savings. Negotiating favorable terms and conditions may be useful for cost-conscious manufacturers.

It's critical for manufacturers and businesses to conduct an intensive price analysis that considers no longer only the raw cloth fee but also processing costs, stop-use overall performance, and any potential downstream savings. Additionally, the unique necessities of the utility and the preferred houses of the fabric ought to guide the fabric selection procedure.

简体中文

简体中文 English

English