Recycled plastic pellets appropriate for injection molding are produced through the recycling of post-patron or put up-commercial plastic waste. These recycled plastic pellets are supposed for use in injection molding processes, wherein they may be melted and shaped into various plastic products. Here are a few key considerations and characteristics of recycled plastic pellets suitable for injection molding:

Material Type:

The sort of recycled plastic used inside the pellets can vary. Common materials include polyethylene (HDPE, LDPE), polypropylene (PP), polyethylene terephthalate (PET), and others. The particular kind of plastic depends at the supply of the recycled fabric.

Quality and Consistency:

Recycled plastic pellets need to meet excellent requirements and exhibit consistency in terms of color, length, and composition. This ensures uniformity in the injection molding method and the very last products.

Contamination Control:

The recycling system have to successfully take away contaminants from the plastic waste. Contaminants can encompass residues from labels, adhesives, or other materials that might be present within the unique plastic objects.

Melt Flow Index (MFI):

The melt drift index is an important belongings that influences how without difficulty the plastic cloth may be processed in injection molding. It is a degree of the flowability of the melted plastic. The MFI of recycled plastic pellets have to be inside the desired variety for injection molding.

Color Options:

Recycled plastic pellets for injection molding are often to be had in various hues. Manufacturers might also provide both herbal (unpigmented) and colored pellets primarily based at the necessities of the quit product.

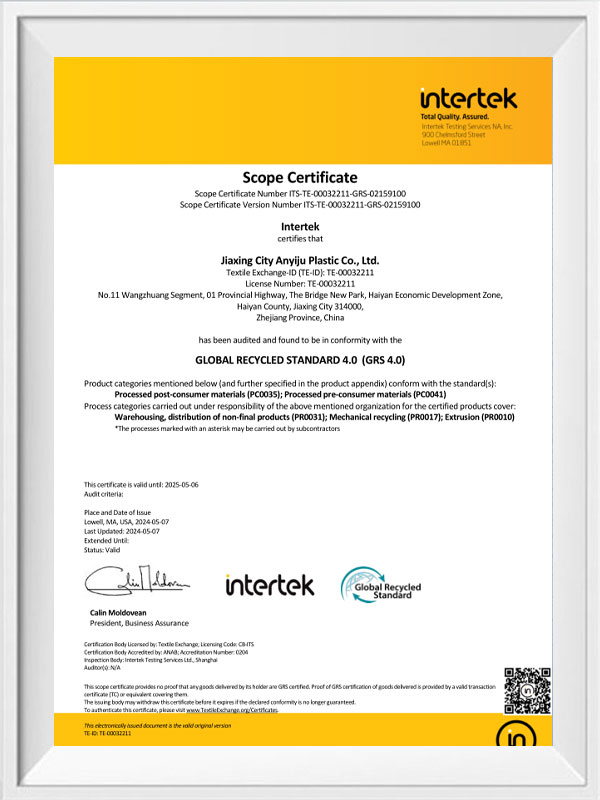

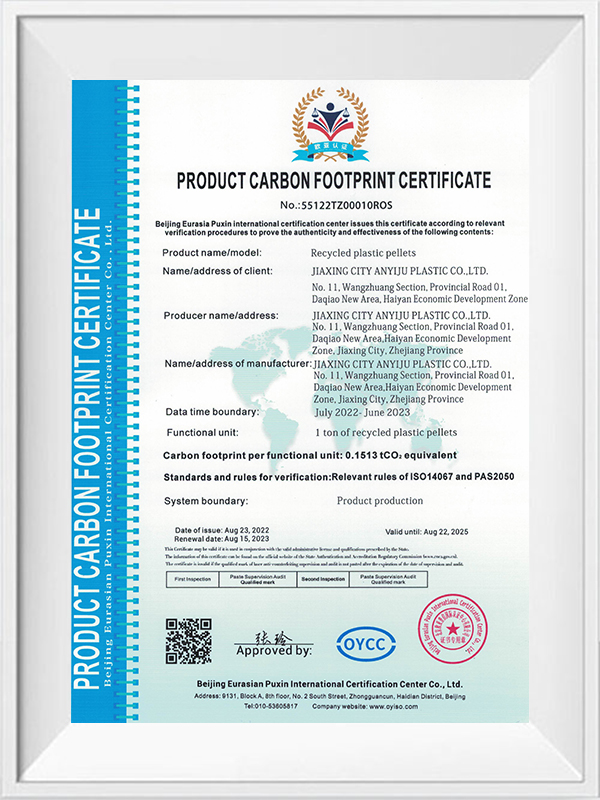

Certifications:

Manufacturers of recycled plastic pellets may additionally achieve certifications to verify that their merchandise meet particular enterprise or regulatory requirements. Certifications can offer assurance concerning the best and sustainability of the recycled fabric.

Compatibility with Equipment:

Recycled plastic pellets have to be well matched with trendy injection molding gadget. Manufacturers using recycled substances regularly layout their products to imitate the processing characteristics of virgin materials.

Sustainability Claims:

Recycled plastic pellets are considered a sustainable option, and manufacturers may additionally offer data on the proportion of recycled content inside the pellets. This facts may be treasured for companies aiming to beautify the sustainability of their merchandise.

Supply Chain Transparency:

Manufacturers may additionally provide details about the sourcing and processing of the recycled plastic. Transparent deliver chain statistics lets in quit-customers to make knowledgeable choices approximately the environmental impact of the cloth.

Applications:

Recycled plastic pellets suitable for injection molding can be used in a extensive range of packages, inclusive of packaging, automobile elements, patron goods, and greater.

Before deciding on recycled plastic pellets for injection molding, it's critical for producers to talk with providers, request samples, and ensure that the recycled fabric meets the unique requirements in their intended applications and manufacturing methods.

简体中文

简体中文 English

English